Join World's Fastest Growing B2B Network

| MOQ | 1 Set/Sets |

| Applicable Industries | Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction w | Condition | New |

| Place of Origin | Shandong, China | Brand Name | Xinren |

| Structure | Plate Heat Exchanger | Liquid Flow Rate | 2.5m/s |

| Maximum Working Pressure | 1.6Mpa | Weight | 100~5000kg |

| Dimension(L*W*H) | customized | Certification | CCC, ce, CSA, SGS |

| Warranty | 2 years | After-sales Service Provided | Free spare parts, Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support |

| Product Name | Industrial gea/milk plate heat exchanger price pasteurizer 3 stage |

Product name:

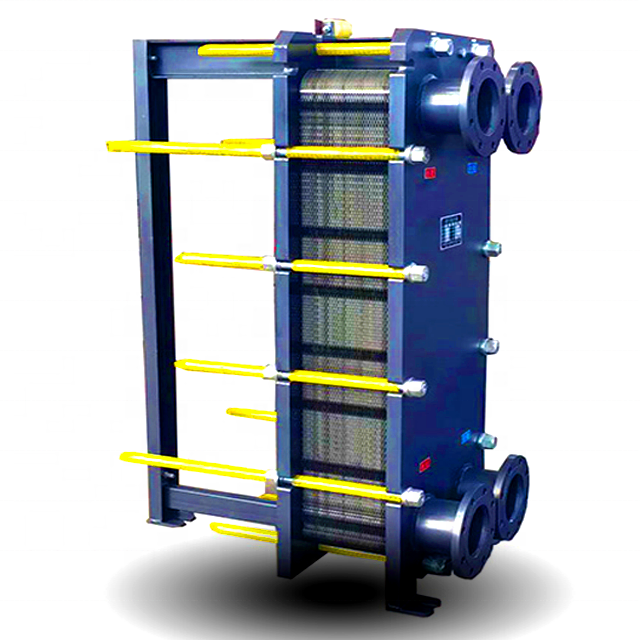

High quality Xinren plate heat exchanger

Industrial gea/milk plate heat exchanger price pasteurizer 3 stage

1, plate selection plate type or ripple form should be based on the actual needs of the plate heat exchanger application. For the large flow allow pressure drop small situation, should choose the small resistance of the plate type, the opposite choice of large resistance plate type. Depending on the fluid pressure and temperature, determine whether you are able to choose a removable or brazing type.

It is not appropriate to select the plate area is too small when determining the plate type, so as not to have too many plates, the flow rate between the plates is too small, and the heat transfer coefficient is too low.

Industrial gea/milk plate heat exchanger price pasteurizer 3 stage

2, pressure down school core in Kangjinghui plate heat exchanger design selection, pressure drop is also a certain requirement, so it should be nuclear.

If the check-in nuclear pressure drop exceeds the allowed pressure drop, the design selection calculation needs to be re-calculated until the process requirements are met.

Industrial gea/milk plate heat exchanger price pasteurizer 3 stage

3, process and runner selection Process refers to a set of parallel runners in the same flow direction of a medium in a heat exchanger, while a flow channel refers to a medium flow channel consisting of two adjacent plates in the current channel. In the process of plate heat exchanger selection, the process combination form should be calculated according to heat exchanger and fluid resistance, and be determined according to the requirements of the process conditions. Try to make the convection heat exchange coefficient in the cold and hot water runner equal or close, so as to obtain the best heat transfer effect.

Because the convective heat exchange coefficient is equal or close on both sides of the heat transfer surface, the heat transfer coefficient is obtained a larger value.