Join World's Fastest Growing B2B Network

| MOQ | 1 set |

| Port | Ningbo for polyurethane machine |

| Packaging | sea worthy wooden box for Polyurethane PU Foam Pouring Low Pressure Machine For 3D Decorative Wall Panel Making |

| Lead Time | 1 month |

| Processing Type | Foaming Machine | Name | polyurethane machine |

| Filter | self-cleaning filter | Material feeding | automatic feeding system |

| Control system | PLC | Metering pump | precise metering |

| Foam type | flexible foam | Output | 90~450kg/min |

| Tank volume | 500L | Color | cream-colored/ orange/ blue |

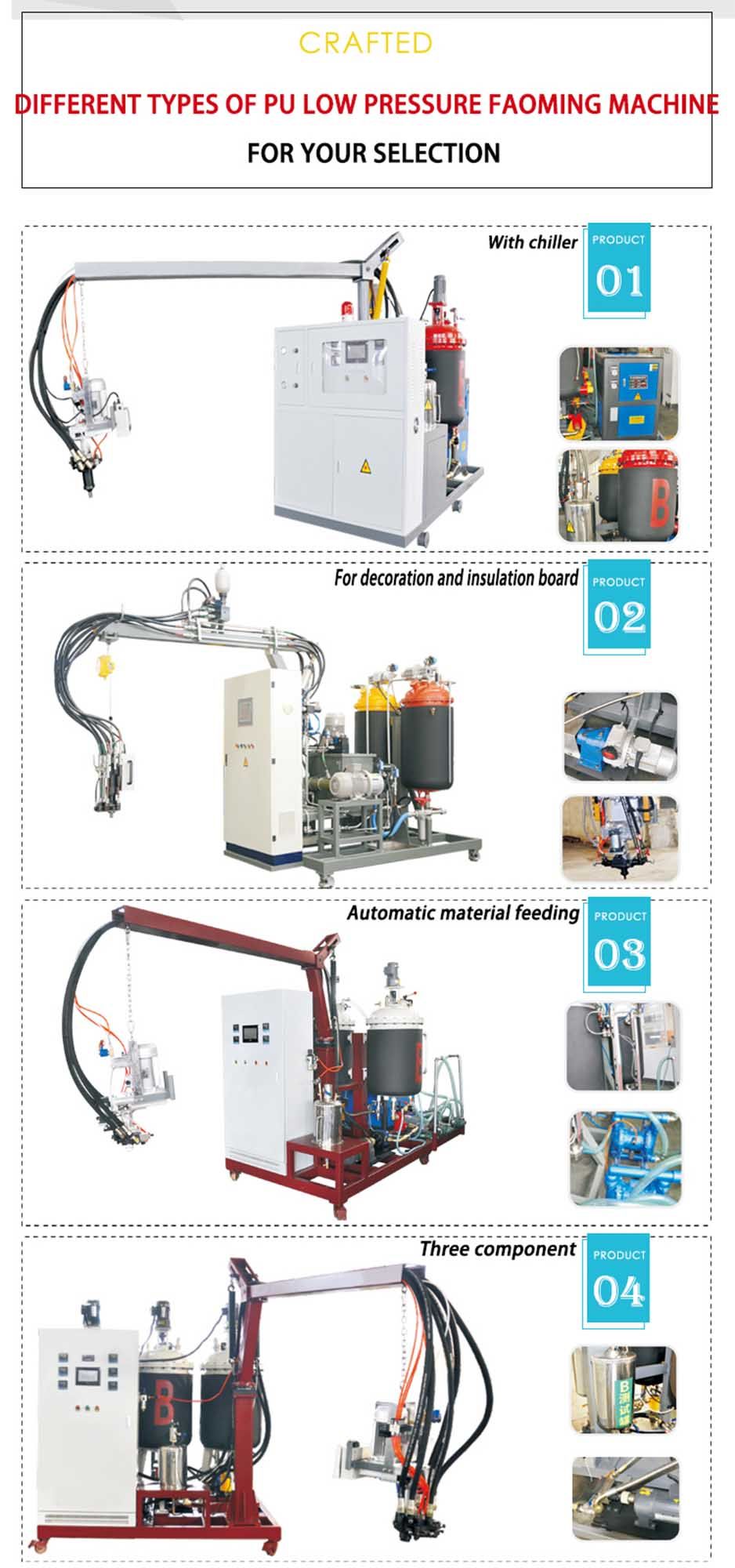

Polyurethane foaming machine, has the economical, convenient operation and maintenance, etc, can be customized according to customer's request various pours out of the machine.

This polyurethane foaming machine uses two raw materials, polyurethane and Isocyanate. This type of PU foam machine can be used in various industries, such as daily necessities, automobile decoration, medical equipment, sports industry, leather footwear, packaging industry, furniture industry, military industry.

This is the storage tank A and B tank of the polyurethane low

pressure machine. Polyurethane and Isocyanate raw materials are

separately installed.

Material

of the tank: SS304

Size

of feeding flange: φ150

Capacity:

250L

Quantity:

2

The mixing head adopts floating mechanical seals, and its high

shear mixing screw head, which can mix two materials

(Polyurethane and Isocyanate) with better performance.The raw

materials are stirred at high speed in the mixing chamber by

stirring blades to achieve a mixing effect, so that the liquid is

uniformly sprayed to form a desired product.

1.

Fully controlled by SCM (Single Chip

Microcomputer).

2.

Using PCL touch screen computer. Temperature,pressure, revolving

speed display system.

3.

Alarm function with acoustic warning.

Polyurethane low pressure machine can be used to manufacture 3D soft bag background wall panels. The soft bag made of polyurethane material has a good decorative effect, a three-dimensional effect, soft texture, and sound insulation, anti-collision, moisture-proof and so on.

Yongjia Polyurethane Co., Ltd. is a professional machinery manufacturer in PU industry combined with design, development, production. Founded in 2013, the construction area of over 10,000 square meters, is the China forefront polyurethane technology company. At present our company's products range covers:high pressure pouring machine, low pressure foaming machine, PU spraying foam machine, PU elastomer casting machine, also we customize to make production line according to clients requirement,like in flexible foam system we make the lines: PU shoe /sole/insole production line(Egypt),anti-fatigue mat production line(India),memory pillow production line(Iran),Albania,elastic ball production line(Mexico),car seat and cushion production line(Morocco),PU slow rebound ear plugs line(India);rigid foam system we make the line:PU decorative molding crown cornice line(Saudi Arab), float trowel making line(Saudi Arab, Pakistan), cold storage panel production line(Uzbekistan),sandwich panel production line(Iraq).Elastomer line:forklift wheel casting line(lran);coal sieve screen select line(Russia).

1. Professional and patient consulting service to help you find the suitable solution.

2.Further negotiation about the technical details, machine configuration, price basis, payment term and delivery time.

3.Powerful control of the machine production schedule and quality, and keep you posted about details in time.

4.Free training in our plant during machine inspection. Or photos and video of the machine and package for your confirmation before shipment.

5.Quick and safe shipment as per your requirement including the booking ,container loading, and shipping documents.

6.For technical support, we can help you online by email and phone, also we can send technicians to your site if necessary.

7.For the spare parts, we will supply the parts for free during one year guarantee period, also the parts supplying at original cost after that .

8.We give an accessory box for free.

9.We offer development solutions for raw material formulations.

10.If you need to visit the factory, we will arrange for personnel to pick up the airport.