Join World's Fastest Growing B2B Network

| Place of Origin | China | Condition | New |

| Applicable Industries | Advertising Company, Manufacturing Plant, Printing Shops, Machinery Repair Shops, Retail, Energy & Mining, CNC engraving | After Warranty Service | Video technical support, Online support, Spare parts |

| Local Service Location | None | Showroom Location | None |

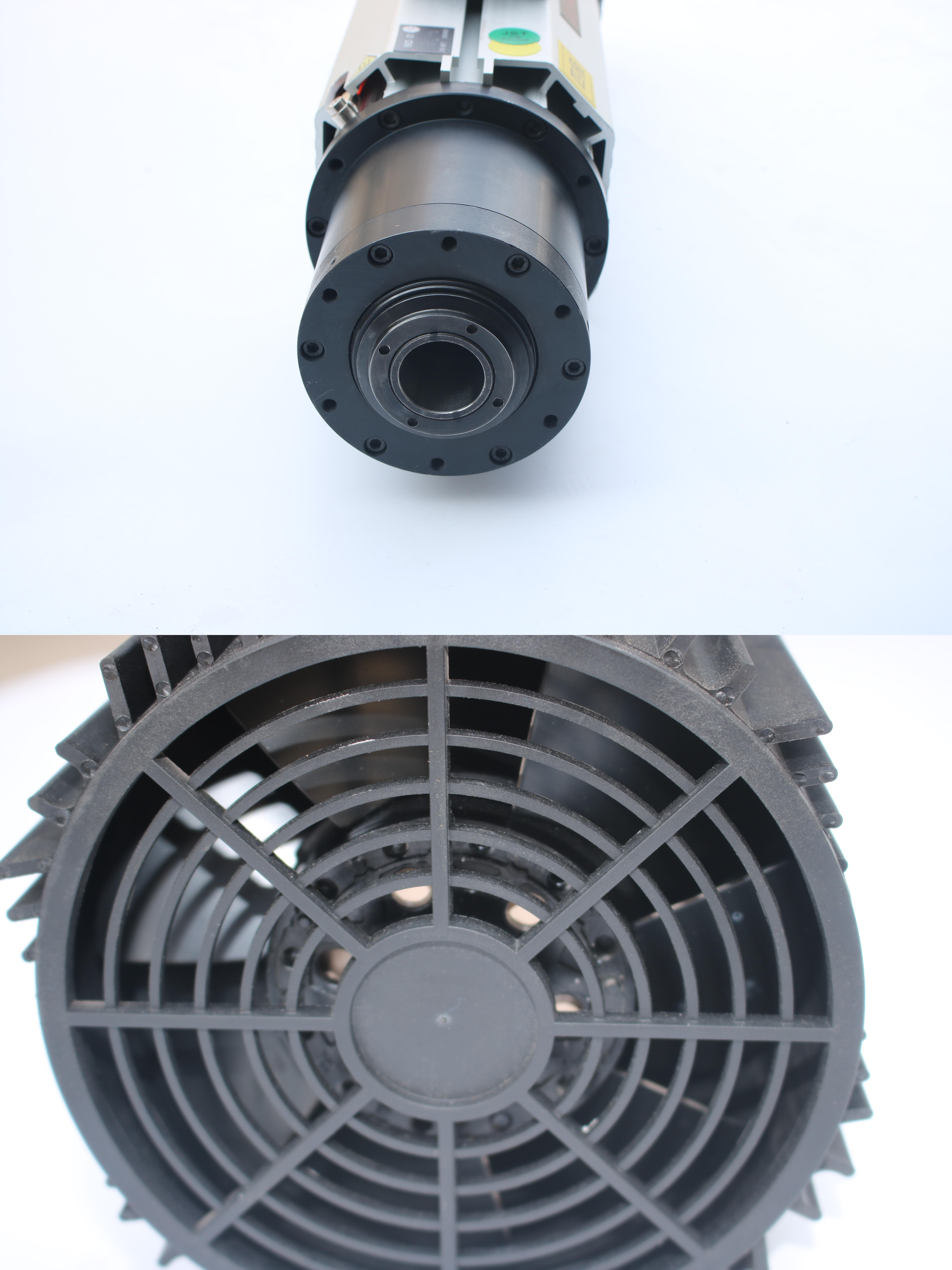

| Brand Name | JST | Model Number | JGLF-9KW BT40 |

| Application | Grinding | Maximum Torque | 3.6-7.2Nm |

| Drive | Motor | Operating Speed | 12000-24000rpm |

| Warranty | 6 months | After-sales Service Provided | Free spare parts, Online support, Video technical support |

| Joint of nose | BT40 | Power | 9KW |

| Voltage | 220/380V | Current | 15.7/27.4A |

| Frequency | 400-800Hz | Cooling | Air cooling |

| Lubrication | Grease |

| Joint of nose | BT40 |

| Power | 9KW |

| Voltage | 220/380V |

| Current | 15.7/27.4A |

| Frequency | 400-800Hz |

| Cooling | Air cooling |

| Lubrication | Grease |

To provide quality products at the same time to improve after-sales support

We have competent R&D Group and expe- rienced engineers

We have own assem- bling factory and mold factory

Professional team to provide you with efficient service