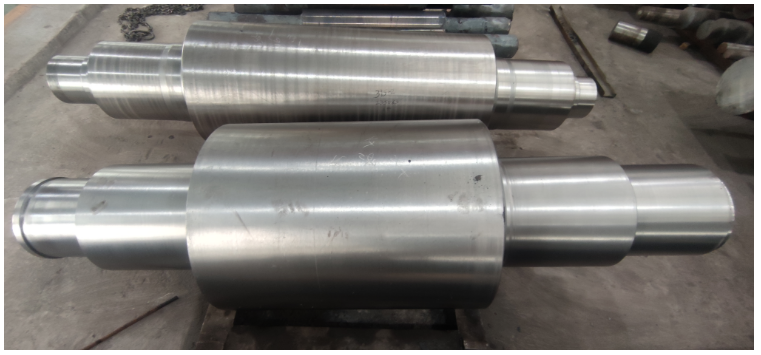

Our Mill Roll is mainly used for cold

roll mills, including supporting roll,

middle roll, working roll and

straightening roll.

We have 5 medium frequency furnaces and

5 electric slag heavy furnaces, which

can produce 1 ton-18 tons of various

types of alloy steel, with an annual

capacity of 10,000 tons. The main

characteristics of electroslag

remelting are that it can flexibly

produce various types of special steel

in size and batch, with pure

composition, uniform and dense crystal

structure.

Digital display computer temperature

control natural gas heating furnace can

accurately control the heating

temperature of raw materials.

800T fast forging machine can quickly

forge products, 3150T and 5000T oil

press can forge heavy-duty axle

products. They can guarantee the

forging ratio required by the product,

and ensure a good microstructure.

More than 20 digital display resistance

furnaces can anneal, quench andtemper ,

so as to ensure the mechanical

properties of the product.

We adopt large lathes and grinders to

ensure the size accuracy and roughness

of the rolls.

Production

Process

Inspection

SYI

regards Quality as the essential part

of our business success. Based on your

requirements, we have raw material

in-coming inspection, process control

and pre-shipment inspection. With

advanced test equipment such as

spectrometer, CMM, tensile strength

tester, microstructure microscope,

hardness tester and etc, SYI is able to

apply sufficient chemical and physical

inspection.

According

to your request, we are also capable to

do X-Ray, Magnetic Testing, Ultrasonic

Testing and Penetration

Testing.

Company

About

Us

SYI provides OEM Casting & Forging

services based on your drawings ,

samples , or just an idea ! After

technical analysis and individual QCP

for each project , the most suitable

manufacture process will be

recommended.

SYI starts our business since

1990 ’ s of machined and

un-machined in a variety of

industry . We have over

100,000 products till now

with the support of a

specialized team including 50

engineers , inspectors and

customer services .

Cooperative Brand