Join World's Fastest Growing B2B Network

| MOQ | 2 Piece/Pieces |

| Place of Origin | Shandong, China | Brand Name | HEXIN |

| Model Number | HX61058 | Material | Stainless Steel |

| Application | Industry machinery | Dimensions | customized |

| Certification | ISO9001 | Surface | Polishing |

| Standard | GB,JIS,AISI,ASTM,SAE,EN,DIN | Finish | Sand Blasting,Polishing |

| Inspection | the third party, in house |

catalyst reformer tubes for hydrogen by centrifugally cast tubes and return bends elbows with nickel alloy 2.4879 HX61058

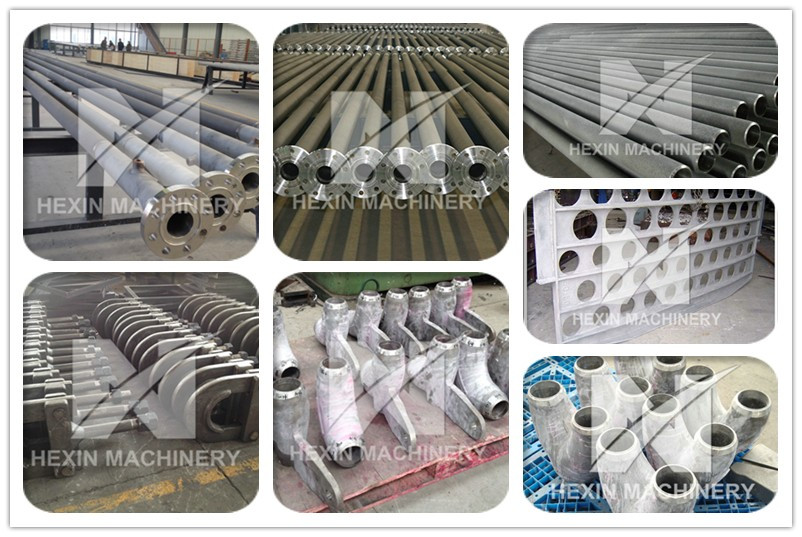

Qingdao Hexin Machinery Co., Ltd. are professional

manufacturer for Ethylene cracking furnace radiant section

tube parts include centrifugal casting tube , centrifugal

casting tube bending , static casting pipe fittings , forgings,

rolled tubes and other components. Use Metal centrifugal

casting process , molten steel is cast into a variety of tube

blank under centrifugal force ,through deep hole boring machine

boring the hole, lathe groove welding , assembly and welding to

be long tube .

Qingdao Hexin Machinery Co., Ltd. specializes Furnace tubes for

hydrocarbon steam reforming hydrogen equipment , used in

various types of hydrocarbon feedstock steam reforming hydrogen

plant , widely used in oil refineries, chemical plant,

metallurgical direct reduced iron (DRI )and other industries,

and petrochemical industry has the largest demand for hydrogen

. Global oil refineries, chemical plants provide more than 90%

of hydrogen used the technology of hydrocarbon steam conversion

method . Hydrocarbon steam reforming hydrogen plant , equipment

including : an inlet manifold , reformer tubes , outlet

manifold and pigtail tubes. The reformer tube use centrifugal

casting process produce to produce, working temperature is 900

ºC -1000 ºC, is the important equipment for hydrogen reformer

furnace.

Material grades is in strict accordance with standard for

customers in different countries, commonly used material grades

:

ZG40Cr25Ni35Nb,ZG40Cr35Ni45Nb,HP-Nb,HT50,GX40NiCrSiNb35-26,GX40NiCrNb45-35,G-NiCr28W,SCH24XNb

General centrifugal casting products supply specifications:

Reformer tube: OD 100mm-300mm,wall thickness 8mm-20mm;

Hot wall manifold: OD 100mm-400mm,wall thickness

10mm-40mm;

| Item | catalyst reformer tubes for hydrogen by centrifugally cast tubes and return bends elbows with nickel alloy 2.4879 HX61058 |

| Usage | Used in various types of hydrocarbon feedstock steam reforming hydrogen plant |

| Process | Centrifugal/spun casting method for roll body, precision casting of assembly shaft head. |

| Specifications |

General centrifugal casting products supply

specifications: Cracking tube: OD 50mm-200mm,wall thickness 5mm-20mm; Manifold: OD 100mm-400mm,wall thickness 10mm-40mm; Static casting supply specifications : 90°elbow,180°elbow,tee , palm tube, three-dimensional shaped elbow , hanging pieces etc. |

| Technology | Chemical analysis by spectrometer for each heat,eddy current test,pressure test ,thickness test , PT 100%(liquid penetrant test),VI(visual inspect)100%,dimensional check. |

| Material | ZG40Cr25Ni35Nb,ZG40Cr35Ni45Nb,HP-Nb,HT50,GX40NiCrSiNb35-26,GX40NiCrNb45-35,G-NiCr28W,SCH24XNb |

| Products |

Reformer tubes Cracking tubes Cast tube sheets Cast Brackets and guides Cast Return bends & plug Headers Furnace observation doors Air preheater |

1. Q: If we don't have drawing, can you make drawing for me?

A: Yes, we make the drawing of your sample and duplicate the sample. Our engineer also provide professional design idea for your reference.

2. Q: What is material for your products?

A: Commonly used material is ZG4Cr25Ni20Si2, ZG40Ni35Cr25Nb, ZG45Ni48Cr28W5Si2, 1.4848, 1.4852, 2.4879 and so on.

3. Q: How are the qualities of your products?

A: The technician and production executives of our company has more than 30 years experience for heat resistant alloy centrifugal casting and static casting, has accumulated rich production experience and valuable technological parameters.

4. Q: What is your technical condition for radiant tubes?

A: The process is spun cast for tubes, investment casting for elbow, forging for flange, machining, machining, welding.

5. Q: What inspection items will you do?

A: Chemical analysis by spectrometer ofr each heat, eddy current test, pressure test, thickness test for roll tube, PT 100% (liquid penetrant test), VI 100% (visual inspection), dimensional check, radiographic test (x-ray) for welds is available on request, but extra cost will be charged.