Join World's Fastest Growing B2B Network

Xmake is a collaborative manufacturing platform for non-standard components with CNC machining process, sheet metal fabrication process and 3d printing process, providing prototype, customized and batch manufacturing services for consumer electronics, energy, environmental protection, equipment manufacturing, medical equipment, automobile manufacturing, scientific research and universities.

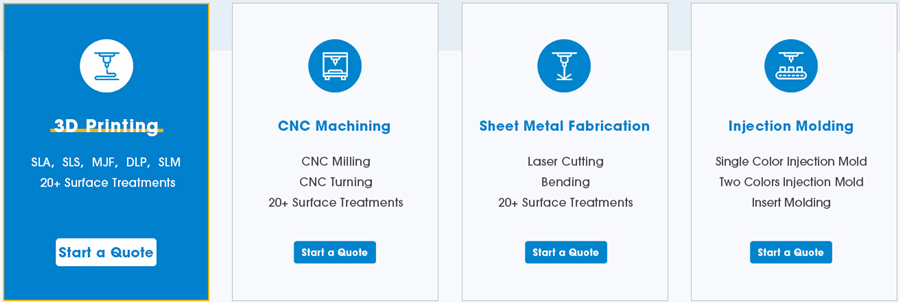

The machining services we provide are listed below.

1. CNC machining service 3 axis 4 axis 5 axis

2. Sheet metal fabrication service

3. 3D Printing

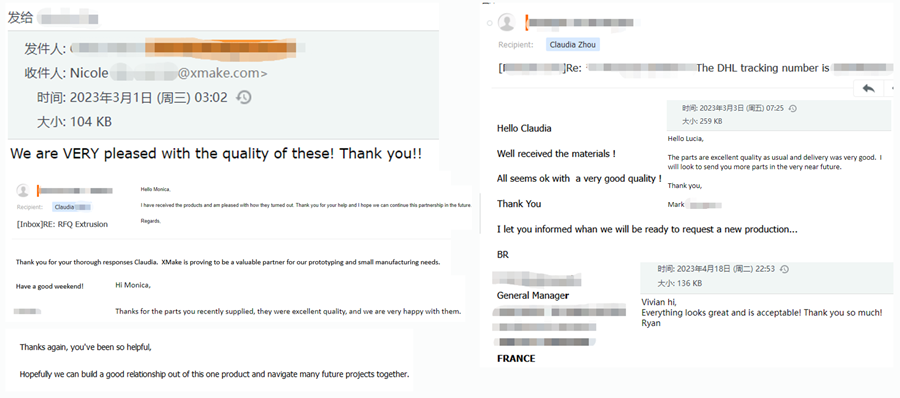

Below are the feedbacks from our customers.

The quality control process in the CNC industry is a systematic approach aimed at ensuring that CNC machined products meet the expected standards of quality. Here's an overview of a common quality control process in the CNC industry:1.Development of Specifications and Standards: Establishing relevant industry specifications and standards, such as ISO 9001 Quality Management System and industry-specific standards. These specifications and standards provide the basic framework and requirements for the quality control process.2.Design and Process Planning: Ensuring that product design and process planning align with quality requirements. This includes utilizing CAD/CAM software for product design and simulation, developing process flows, selecting appropriate tools, and determining machining parameters.3.Material Procurement and Inspection: Selecting qualified material suppliers and developing procurement plans. Conducting material inspection and acceptance, including visual inspections, chemical composition analysis, and mechanical property testing, to ensure that materials meet the specified quality standards.4.Calibration of CNC Equipment and Tools: Regular calibration of CNC equipment and tools to ensure their accuracy and performance meet the specified requirements. Calibration involves checking machine tool geometries, axial precision, tool length compensation, and other relevant parameters.5.Process Control and Operating Procedures: Establishing detailed process control and operating procedures to ensure consistency and traceability in the machining process. Procedures should include setting appropriate machining parameters, defining process sequences, outlining inspection requirements for each operation, and specifying operating methods.6.Online Monitoring and Measurement: Utilizing sensors and measurement devices for real-time monitoring and measurement of key parameters and quality indicators during the machining process. Real-time data collection and analysis facilitate timely detection and correction of potential issues.7.Inspection and Testing: Conducting comprehensive product inspections and testing, including dimensional measurements, visual inspections, functional tests, etc., to verify product quality and performance. Utilizing professional measuring tools and equipment and performing inspections and tests according to relevant standards.8.Traceability and Record Management: Establishing a traceability system to record and manage key machining parameters, quality data, and product information. The traceability system allows for tracking the machining process and quality information, enabling problem traceability and quality improvement when necessary.Process Review and Continuous Improvement: Conducting regular internal quality audits and process reviews to evaluate the effectiveness and consistency of the quality control process.

Quality, Delivery, and Service Commitment for Xmake manufacturing service.1. Quality Commitment:We are committed to delivering excellent quality to meet the expectations and requirements of our customers. We take the following measures to ensure product quality:Utilizing advanced equipment and technology to ensure precise and consistent manufacturing results.Following strict quality management systems that encompass the entire process, from raw material procurement to finished product inspection.Conducting comprehensive product testing and inspection to ensure compliance with industry standards and specifications.Continuously improving our processes and techniques to enhance product quality and performance.2. Delivery Time Commitment:We understand the importance of timely delivery to our customers. We commit to:Adhering to agreed-upon delivery dates with our customers and making every effort to deliver products on time.Conducting a reasonable evaluation of the required manufacturing time upon order placement and maintaining clear communication with customers to ensure delivery time meets both parties' expectations.Promptly communicating with customers in case of any potential delays that may affect the delivery timeline and providing solutions to minimize inconvenience.3. Customer Service Commitment:We are dedicated to providing excellent customer service and ensuring comprehensive support throughout our collaboration. We commit to:Offering professional technical consultation and support to assist customers in making informed decisions regarding product design and manufacturing.Responding promptly to customer inquiries, issues, and complaints, and taking appropriate measures to resolve them.Establishing long-term partnerships with customers, fostering communication and collaboration for mutual success.We will make every effort to fulfill these commitments, meet customer needs, and build strong business relationships. If you have any questions or specific requirements, please feel free to contact us. We are here to serve you wholeheartedly.

| Business Type | Manufacturer, Distributor/Wholesaler, Buying Office |

| Company | Yungong Industrial Technology (Shenzhen) Co., Ltd |

| Main Products | CNC Machining,3D printing,Metal Sheet Fabrication |

| Website | www.xmake.com |

| Established Year | 2019 |

| City / State | Shenzhen , Bao'an District |

| Country | China |

| Address | Room 808 Tangwei Commercial Building,Bao,An District,Shenzhzen,China |

| Location | shenzhen |

| Factory Size | 20000 |

| Total QC Staff | 405 |

| Total RND Staff | 70 |

| Number of Production Lines | 25 |

| Annual output | 100 million |

| Average Lead Time | 4-10 working days |

| Total Revenue | 100 Million |

| Export Percentage | 50% |

| Nearest Port | Shenzhen |

| Overseas Office |