Join World's Fastest Growing B2B Network

Shandong Guansong Industrial Co.,Ltd. is a professional manufacturer and supplier of various packaging products. Our company consists of 2 packaging factories and take charge of the development of international markets for exporting all kinds of packaging products. Our products include: various FIBC bags, ventilated bulk bags, sling bags, conductive bags, kraft paper and PP (PE) complex bags, valve bags, container liners, flexitanks, BOPP bags, PE food bags and kraft paper bags etc..

The foundation of Shandong Guansong Industrial Co., Ltd. aims to give a full plan of the superiority for all our factories and provide our clients with all sorts of cost-effective and high quality packaging products. Meanwhile, in line with the idea of co-prosperity and development, we provide one-stop and value-added services to our clients. Our group company give an annual output of 6 million pieces of high quality FIBC bags, 50 million pieces of kraft paper and PP(PE) complex bags, 80 million pieces of BOPP bags, 50 million pieces of kraft paper bags, 20 million pieces of PE food bags, 300,000 pieces of container liners, 200,000 pieces of flexitanks and 200million pieces of small PP woven bags.

Our clients are widely from Europe, United states of America, Southeast Asia, Japan, South Korea, Africa, New Zealand and Australia etc.. Shandong Guansong Industrial Co.,Ltd. has obtained most of the domestic and international certificates for our packaging products, including Approval of export for Dangerous goods Packaging issued by China Entry-Exit Inspection and Quarantine Bureau, ISO9001-2015, EN21898-2005, FSC22000, SGS, AIB and Kosher Certificate etc..

Your high quality products, packed with our high quality packaging. Shandong Guansong Industrial Co.,Ltd. is the best partner for all your packaging needs.

At our factory, we understand the importance of producing high-quality FIBC bulk bags for our customers in European countries. To ensure that our bags meet the standards of our customers, we have a detailed quality control process in place.

The first step in our process is to perform incoming raw material inspections.

We inspect all the raw materials used in the production of our bags, such as the fabric, webbing, and thread, to ensure that they meet our high-quality standards. Any material that doesn't meet our standards is rejected.

Once the raw materials have been approved, we move on to the production process.

We have a team of experienced operators who are responsible for closely monitoring the production process. They are trained to identify any issues that may arise during production and take immediate action to correct them.

During the production process, we also perform in-process inspections.

These inspections are performed at various stages of production to ensure that our bags are being made according to the customer's specifications. Any deviations are immediately corrected before the production process continues.

After the bags have been fully produced, we conduct a final inspection to make sure that they meet our customer's standards.

Our final inspection includes a visual and physical examination of the bags to check for any defects, such as holes, tears, or loose threads. We also check the strength of the bags by performing various tests, such as the drop test and the top lift test, to ensure that they can withstand the weight they are designed to carry.

Once the bags have passed our final inspection, they are labeled and packed for shipment. We take pride in delivering high-quality bags to our customers in European countries. We understand the importance of meeting their expectations and strive to exceed them.

In conclusion, our quality control process is a critical component of our production process. We are committed to delivering only the highest quality bags to our customers in European countries. Our team works tirelessly to maintain our high standards, and we are confident in our ability to meet and exceed our customer's expectations.

1. Ethical standards: We will maintain high ethical standards in all our activities. We will not engage in any unethical behavior, including bribery, corruption, or any other form of illegal activity.

2. Compliance with Laws: We will comply with all applicable laws and regulations, and will maintain accurate records and thorough documentation as required by law.

3. Respect for human rights: We will respect the human rights of our employees, suppliers, and customers, and will not engage in any behavior that violates these rights.

4. Environmental responsibility: We will take measures to minimize our impact on the environment and strive to ensure that our operations are sustainable.

5. Fair competition: We will compete fairly and honestly, and will not engage in any practices that could harm our competitors or customers.

6. Quality commitment: We will maintain the highest quality standards for our products and services, and will strive to continuously improve and innovate.

7. Respect for diversity: We will respect and value diversity in all its forms, including race, ethnicity, gender, religion, and sexual orientation.

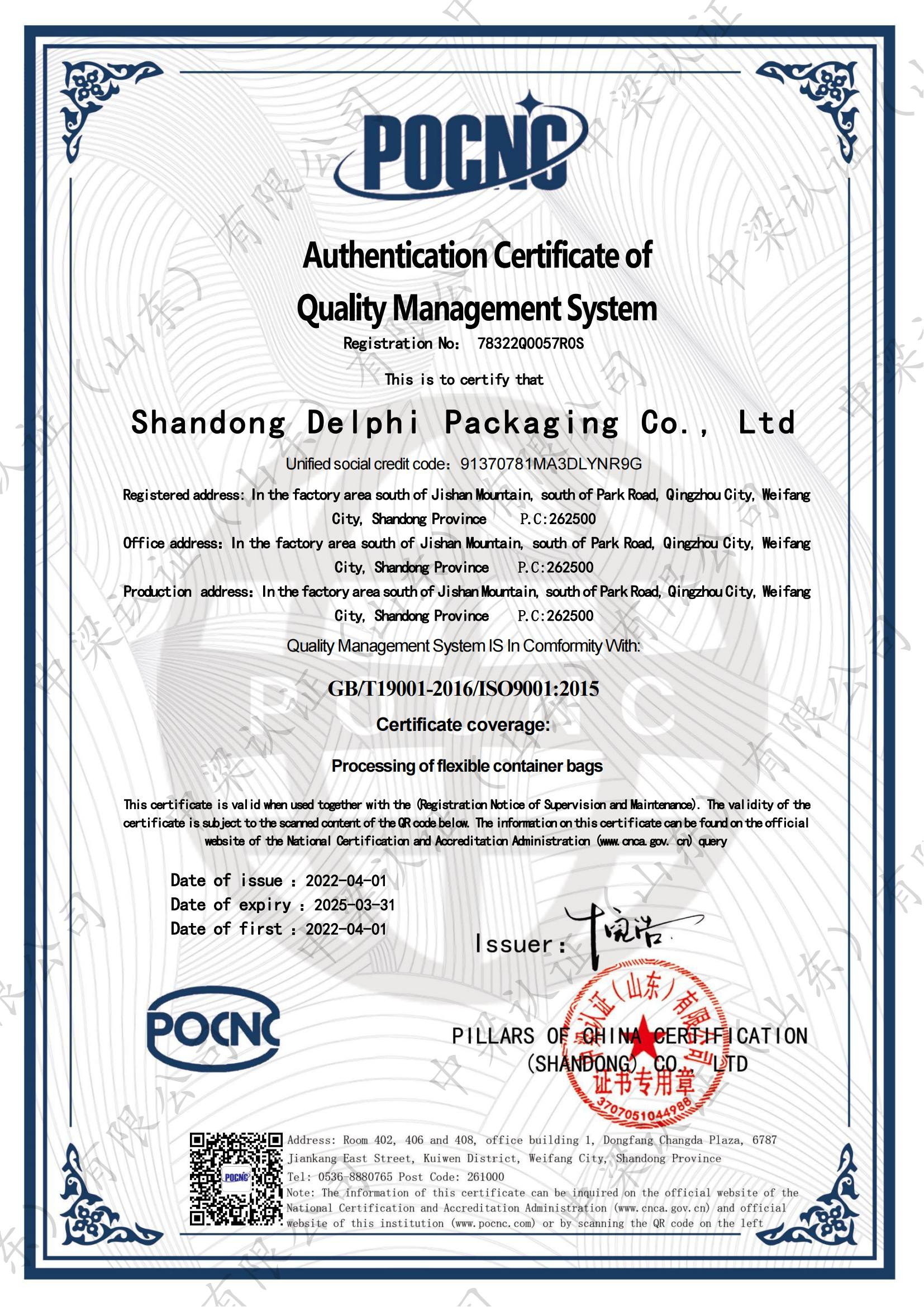

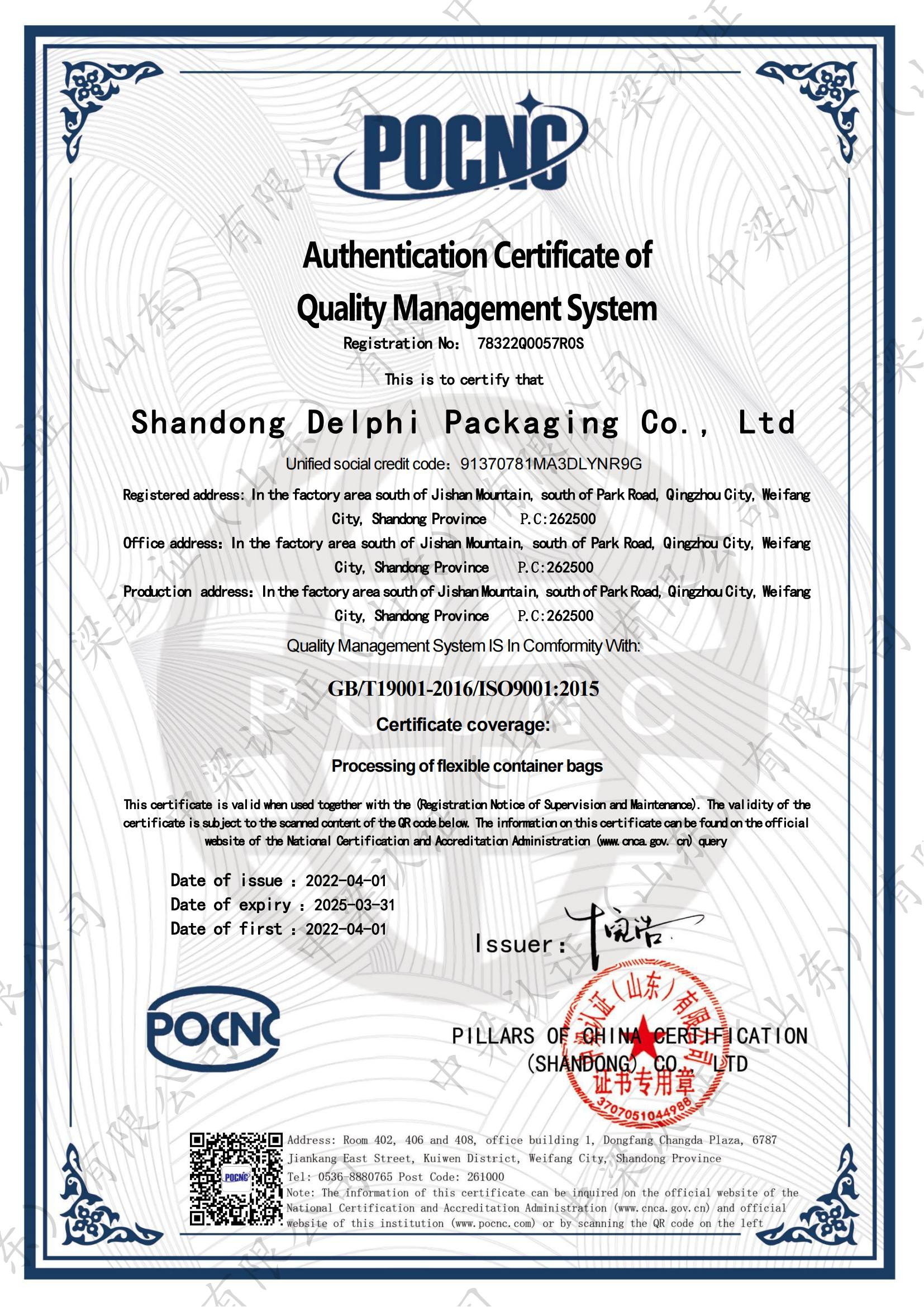

ISO9001-2015

ISO 9001:2015 specifies requirements for a quality management system where an organization needs to demomstrate its anility to consistently provide products that meets customer and appicable statutory and regulatory requirements. Quality Management Systerm in confirmity with GB/T 19001-2006 / ISO9001:2015 Certificate coverage: Processing of Flexible container bags

FSSC22000

Food Safety System Certifiction FSSC22000 scheme for food safety system of the following elements: ISO22000:2018, ISO/TS22002-4:2013 and additional FSSC22000 requirements This certificate is applicable for the scope of following: Manufacturing of plastic flexible bulk container (FIBC) used for food packaging, Including wire drawing, printing and bag making process. Inner material: Polyethylene or Polypropylene Food catagory: - Production of Food Packaging and Packaging Material

| Business Type | Manufacturer, Distributor/Wholesaler |

| Company | Shandong Guansong Industrial Co.,Ltd. |

| Main Products | pp woven bags / pp bulk bag |

| Website | www.ppbigbag.com |

| Established Year | 2009 |

| City / State | ZIBO , SHANDONG |

| Country | China |

| Address | No. 176, XIN CUN WEST ROAD, ZIBO, SHANDONG, CHINA. |

| Brochure | Download |

| Location | Government Resident of Shaozhuang Town, Qingzhou City, Shandong, China. |

| Factory Size | 15000Square meters |

| Total QC Staff | 12 |

| Total RND Staff | 5 |

| Number of Production Lines | 3 |

| Annual output | 10000 METRIC TONS |

| Average Lead Time | 20-25 DAYS |

| Total Revenue | USD150 MILLION |

| Export Percentage | 70% |

| Nearest Port | QINGDAO |

| Overseas Office |