Join World's Fastest Growing B2B Network

Dongguan Luphi Electronics Technology Co., Ltd.(branded as LuphiTouch) was established in 2008. It located in Dongguan, China. The factory covers 4500 square meters. It close to Shenzhen, Guangzhou and Hongkong. To Shenzhen airport is just about 30 minutes and to Guangzhou Baiyun Airport is just about 1 hour. LuphiTouch is a high-tech enterprise for human machine interface assemblies.

Our main business and products include designing and manufacturing various kinds of membrane switches, membrane keypads, graphic overlays, membrane circuits, backlighting membrane keypads like the LED backlighting membrane switches, EL backlighting membrane switches, LGF backlighting membrane switches, capacitive membrane switches, capacitive sensing circuits, printed touch sensors, capacitive font panels and nameplates, labels, PCBA, prototype to middle volume metal + plastic + electronics turnkey assembly projects.

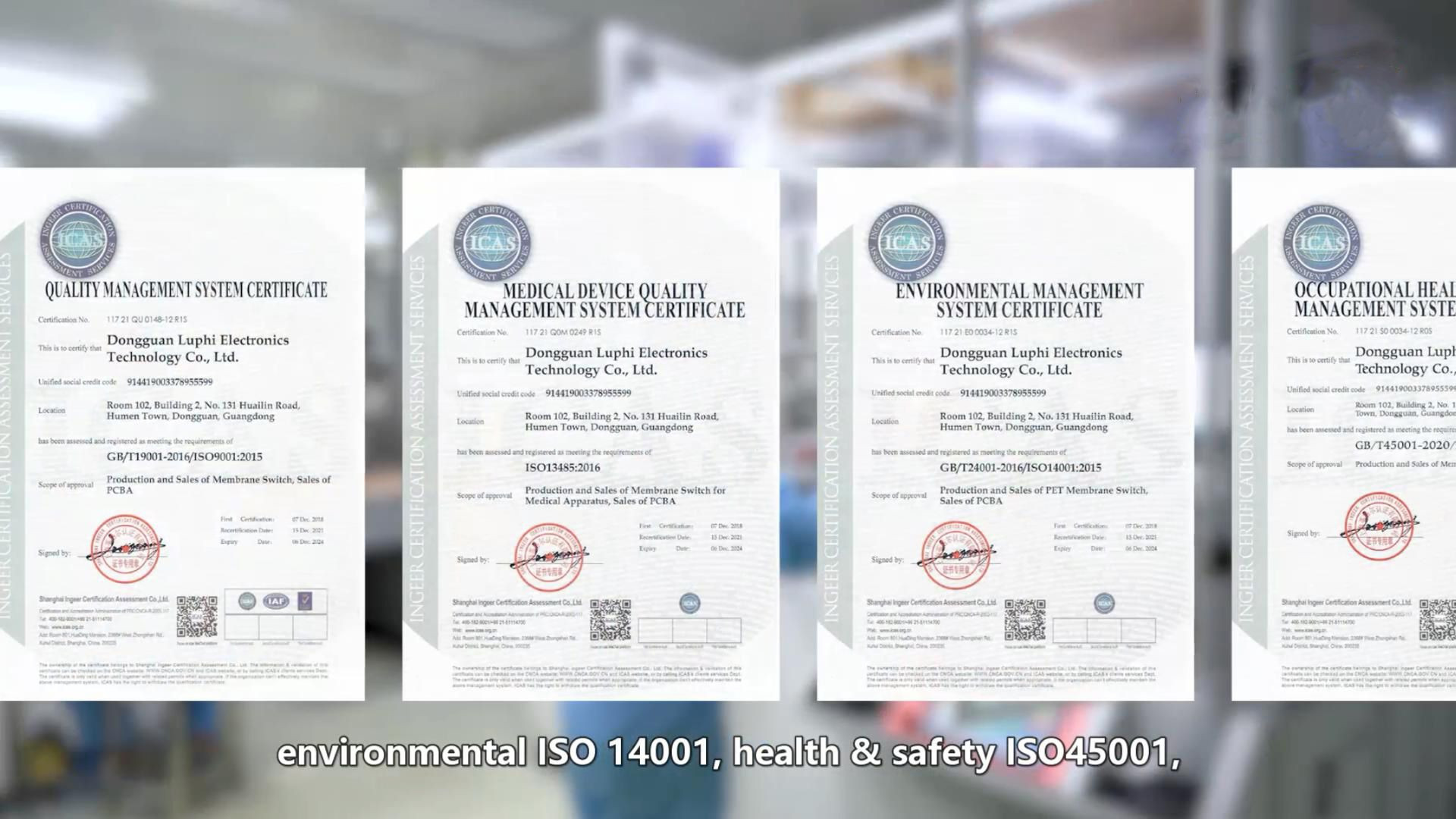

LuphiTouch certified by ISO9001, ISO14001, ISO13485 and ISO45001. We are the first ISO13485 medical quality system certified membrane switch factory in China. Our products and services are widely used on medical, healthcare, household electrical appliances, industry control, vehicles, marine, aerospace, networking, telecommunication, consumer electronics, measuring instruments, military and defence etc. fields.

LuphiTouch,a professional OEM manufacturer of user interface subassembly products.LuphiTouch is located in south of China in Dongguan,and since 2008 the core of its business is manufacturing an export of membrane switches & keypads, capacitive switches, silicone Rubbert keypads, graphic overlays, and touchscreen panels. Besides,they also offer mechanical design and PCBA development, as well as development of single-chip solutions, keypad backlighting, and turnkey assembly. The production of high-tech interface products requires clean and well functioning operations.let's get to know that how LuPhi complies with industry requirements.

The factory has many strengths-we use high quality imported raw materials and have a skillful team of workers,as well as modern production and testing equipment,our facility is certified with ISO 9001,medical ISO13485,environmental ISO14001,health and safety ISO45001, and the production areas are equipped with 10000 and 1000 class cleanrooms.our products obtain main quality certificates for major markets, such as Europe,North America and Australia.

KEY PROCESS OF PRODUCTION

Design: First,the product concept takes shape in the R&D department,where LuPhi's engineers design and create initial samples.before mass production,their PP samples will undergo various function and environmental testing, such as button actuation life testing,high-low temperature constant temperature,and humidity testing,as well as salt-spray & waterproof testing,ink adhesion force testing,click ratio test, and many others.

Once the pre-production samples pass all necessary testing and materials arrive at the factory,production begins.LuPhi uses high-quality imported materials, such as 3M adhesive,Autotex polyester,nikomatic connectors, and many other components.

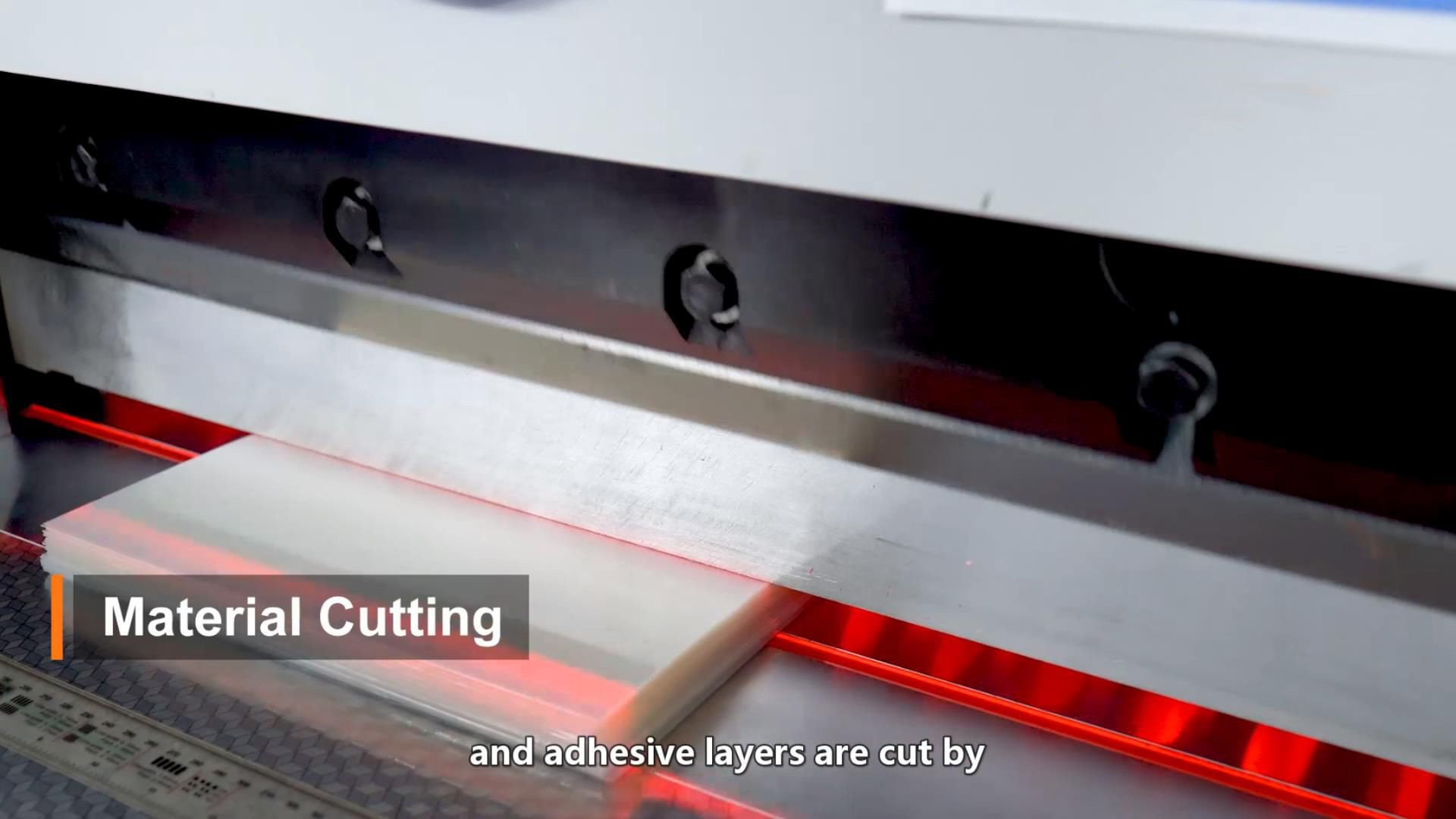

Material Cutting:

The first step of production starts from raw material cutting- where overlay films,circuit films and adhesive layers are cut by automatic cutting machines with high accuracy.

After that,the cut materials are transferred to a silk screen printing workshop,where first the ink is prepared to match the exact color requirements of the customer, and silkscreens are created for printing.

Silkscreen Printing:

Then films and screens are moved to automatic and semi-automatic silk screen printing machines.

Drying:

Following the printing,semi-finished products,are further passed to a baking treatment in a 12-meter drying tunnel until the ink is completely dried and cured, LuPhi also has 4 drying ovens to increase efficiency at this step.

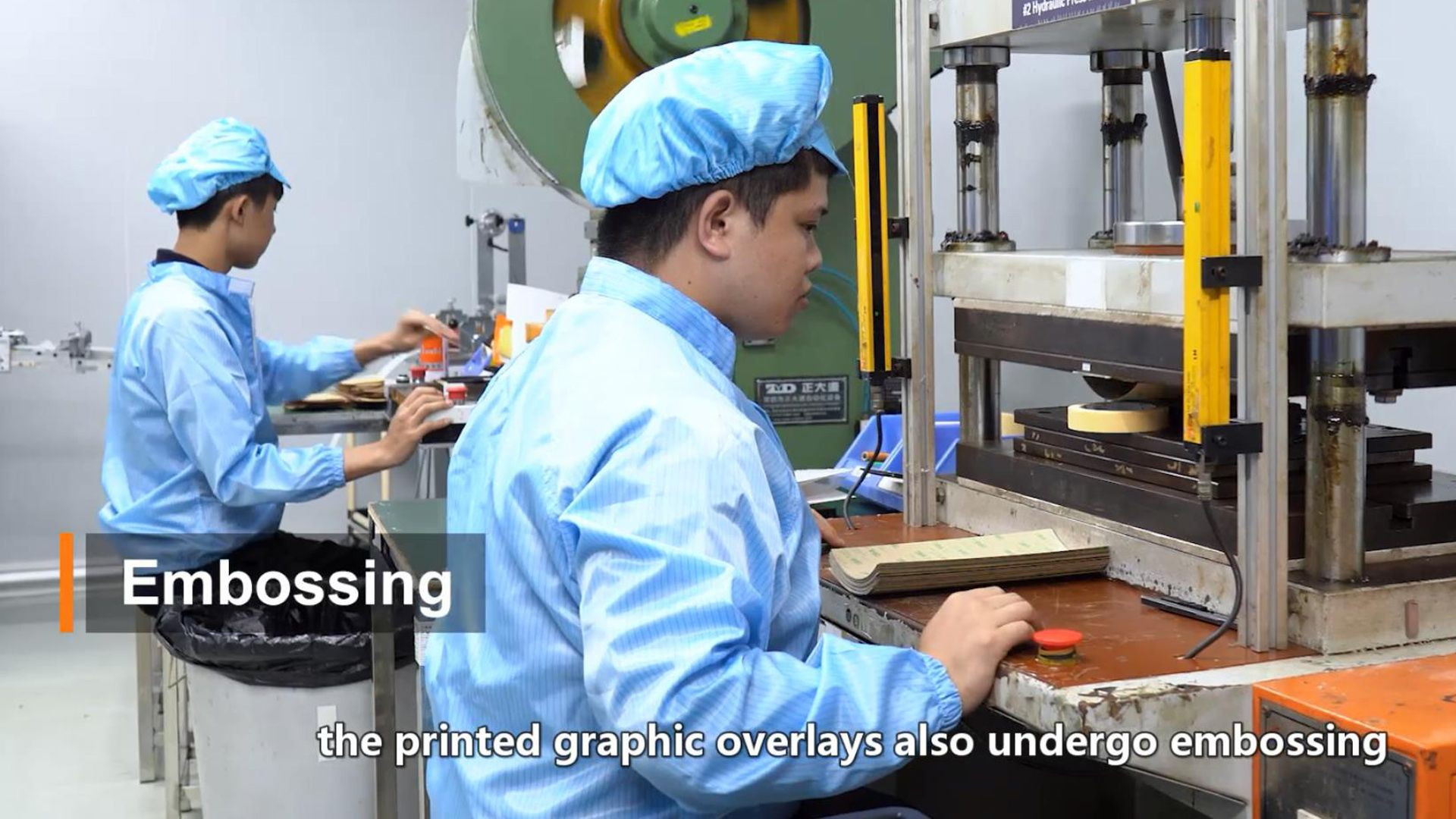

Embossing:

For many membrane switches with embossed buttons,the printed graphic overlays also undergo embossing in semi-automatic embossing machines.

Assembly:

In the end, all layers of the final products, such as graphic layers, adhesive layers, circuit layers and others are assembled and laminated together, creating the about-to-be final membrane switch.

Punching:

After assembly,products are passed to auto die cutting&high accuracy cutting machines to cut out the membrane switch panels and form the final product shape.

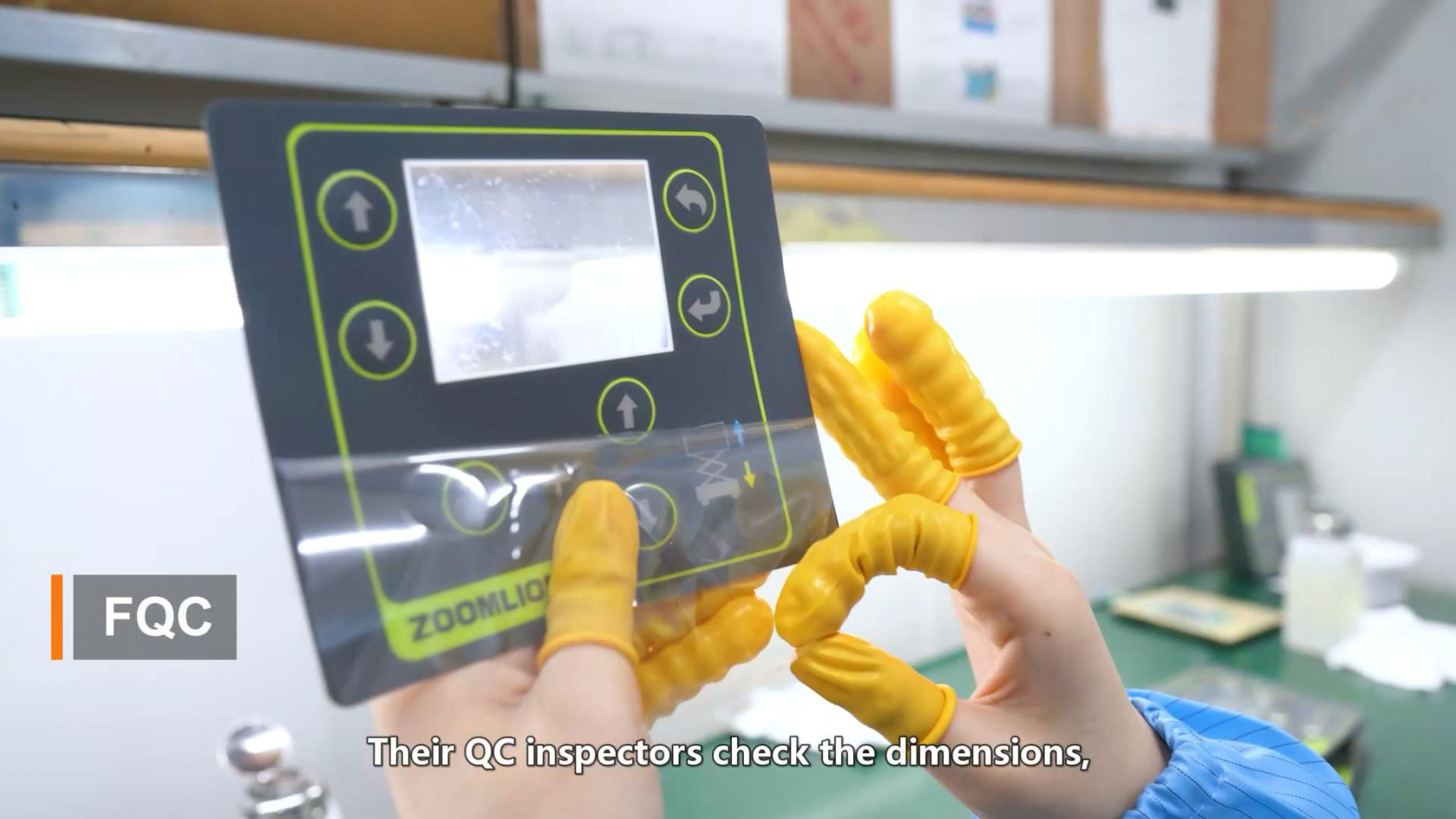

FQC:

At each production step,products are fully inspected with 100% appearance and function check, to ensure that every product received by customers is qualified.

Our QC inspectors check the dimensions, printings, workmanship and electrical functions, which undergo testing twice after the circuit is printed and assembly is finished.

Packing: Once products pass the inspection, they'll be cleaned, packed into inner and expert packaging, and shipped to customers all over the world.

FACTORY AUDIT, SUMMARY:

These have several advantages of the factory-our facility follows : ISO9001, medical ISO13485,environmental ISO14001, health & safety ISO 45001, and production areas are equipped with 10000 class and 1000 class cleanrooms, that guarantees a clean environment for manufacturing. Moreover, LuphiTouch uses high-quality imported raw materials and can support the production of quality membrane switches and touchscreen panels in variety of sizes,designs,and functions.Besides that LuphiTouch have a mature quality control system for monitoring in-line and final product quality, with various appearance and function testing.

Membrane switches operate all sorts of products,from household appliances to industrial and medical equipment.Manufacturer produces quality membrane switches and touchscreen panels in a variety of sizes,designs, and functions. Please visit our factory and see how things operate here!

LuphiTouch,a professional OEM manufacturer of user interface subassembly products.LuphiTouch is located in south of China in Dongguan,and since 2008 the core of its business is manufacturing an export of membrane switches & keypads, capacitive switches, silicone Rubbert keypads, graphic overlays, and touchscreen panels. Besides,they also offer mechanical design and PCBA development, as well as development of single-chip solutions, keypad backlighting, and turnkey assembly. The production of high-tech interface products requires clean and well functioning operations.let's get to know that how LuPhi complies with industry requirements.

The factory has many strengths-we use high quality imported raw materials and have a skillful team of workers,as well as modern production and testing equipment,our facility is certified with ISO 9001,medical ISO13485,environmental ISO14001,health and safety ISO45001, and the production areas are equipped with 10000 and 1000 class cleanrooms.our products obtain main quality certificates for major markets, such as Europe,North America and Australia.

LuphiTouch,a professional OEM manufacturer of user interface subassembly products.LuphiTouch is located in south of China in Dongguan,and since 2008 the core of its business is manufacturing an export of membrane switches & keypads, capacitive switches, silicone Rubbert keypads, graphic overlays, and touchscreen panels. Besides,they also offer mechanical design and PCBA development, as well as development of single-chip solutions, keypad backlighting, and turnkey assembly. The production of high-tech interface products requires clean and well functioning operations.let's get to know that how LuPhi complies with industry requirements.

The factory has many strengths-we use high quality imported raw materials and have a skillful team of workers,as well as modern production and testing equipment,our facility is certified with ISO 9001,medical ISO13485,environmental ISO14001,health and safety ISO45001, and the production areas are equipped with 10000 and 1000 class cleanrooms.our products obtain main quality certificates for major markets, such as Europe,North America and Australia.

KEY PROCESS OF PRODUCTION

Design: First?the product concept takes shape in the R&D department?where LuPhi's engineers design and create initial samples.before mass production,their PP samples will undergo various function and environmental testing, such as button actuation life testing,high-low temperature constant temperature,and humidity testing,as well as salt-spray & waterproof testing,ink adhesion force testing,click ratio test, and many others.

Once the pre-production samples pass all necessary testing and materials arrive at the factory,production begins.LuPhi uses high-quality imported materials, such as 3M adhesive,Autotex polyester,nikomatic connectors, and many other components.

Material Cutting:

The first step of production starts from raw material cutting- where overlay films,circuit films and adhesive layers are cut by automatic cutting machines with high accuracy.

After that,the cut materials are transferred to a silk screen printing workshop,where first the ink is prepared to match the exact color requirements of the customer, and silkscreens are created for printing.

Silkscreen Printing:

Then films and screens are moved to automatic and semi-automatic silk screen printing machines.

Drying:

Following the printing,semi-finished products,are further passed to a baking treatment in a 12-meter drying tunnel until the ink is completely dried and cured, LuPhi also has 4 drying ovens to increase efficiency at this step.

Embossing:

For many membrane switches with embossed buttons?the printed graphic overlays also undergo embossing in semi-automatic embossing machines.

Assembly:

In the end, all layers of the final products, such as graphic layers, adhesive layers, circuit layers and others are assembled and laminated together, creating the about-to-be final membrane switch.

Punching:

After assembly,products are passed to auto die cutting&high accuracy cutting machines to cut out the membrane switch panels and form the final product shape.

FQC:

At each production step,products are fully inspected with 100% appearance and function check, to ensure that every product received by customers is qualified.

Our QC inspectors check the dimensions, printings, workmanship and electrical functions, which undergo testing twice after the circuit is printed and assembly is finished.

Packing: Once products pass the inspection, they'll be cleaned, packed into inner and expert packaging, and shipped to customers all over the world.

FACTORY AUDIT, SUMMARY:

These have several advantages of the factory-our facility follows : ISO9001, medical ISO13485,environmental ISO14001, health & safety ISO 45001, and production areas are equipped with 10000 class and 1000 class cleanrooms, that guarantees a clean environment for manufacturing. Moreover, LuphiTouch uses high-quality imported raw materials and can support the production of quality membrane switches and touchscreen panels in variety of sizes,designs,and functions.Besides that LuphiTouch have a mature quality control system for monitoring in-line and final product quality, with various appearance and function testing.

| Business Type | Manufacturer |

| Company | Dongguan Luphi Electronics Technology Co., Ltd. |

| Main Products | Membrane switch, Rubber switch |

| Website | ISO9001:2015, ISO13485:2016, ISO14001:2015, OHSAS1 |

| Established Year | 2008 |

| City / State | Dongguan , Guangdong |

| Country | Hong Kong |

| Address | 1st/F, Building 3, Hesen Industry Park, No. 131 of Huailin Rd., Huaide Area, Humen Town, Dongguan, Guangdong, China 523926 |

| Location | 1st/F, Building 2, Hesen Industry Park, Huailin Rd., Huaide Area, Humen Town, Dongguan, China |

| Factory Size | 4500 square meters |

| Total QC Staff | 10 |

| Total RND Staff | 8 |

| Number of Production Lines | 4 |

| Annual output | |

| Average Lead Time | shipped 15 days after the payment |

| Total Revenue | |

| Export Percentage | |

| Nearest Port | ShenZhen |

| Overseas Office | Teingesch Touch Display Technology Limited |